Health-based Predictive Maintenance

Prevent Breakdowns & Unplanned Downtime

The fastest way to great 24/7 machine monitoring. Advanced sensors and AI-powered algorithms provide real-time health analysis of equipment, track performance over time, and give you the insights needed to take action before issues arise.

Plan Service

Prevent Costly Downtime

Improve Machine Reliability

Getting Started Has Never Been Easier

Device

Smartphone

Health Analysis

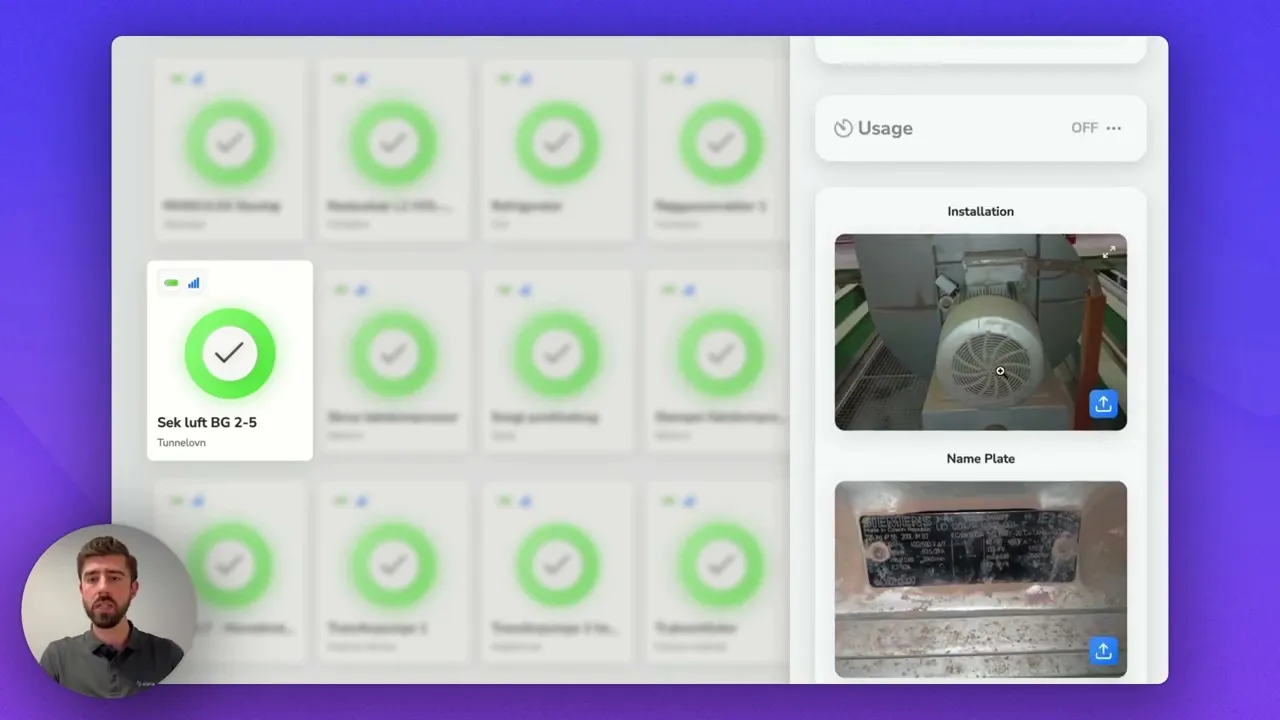

With our technology, there’s no need for complex IT setups or endless configuration. All you need is our sensor device and a smartphone. Simply install the sensor, connect through the app, and start tracking machine health, uptime tracking and maintenance data instantly. It’s that simple.

Main Benefits

Stay Ahead of Breakdowns and Downtime

24/7 monitoring and real-time health analysis identifies issues early, reducing unplanned downtime and keeping production running smoothly.

Increase Productivity Across the Board

Having great data and actionable insights, results in fewer unexpected failures, so your team can focus on maximizing output, not reacting to emergencies.

Stay Competitive with Modern Maintenance Strategies

Adopting newer maintenance strategies like Predictive & Usage-based Maintenance puts you ahead of the curve, aligning with industry best practices and future trends.

Trusted by Top Global Manufacturers

Key Features

2-minute Install

The installation process is quick and intuitive - set up the sensor and connect it to the cloud in just 2 minutes using our easy-to-follow app.

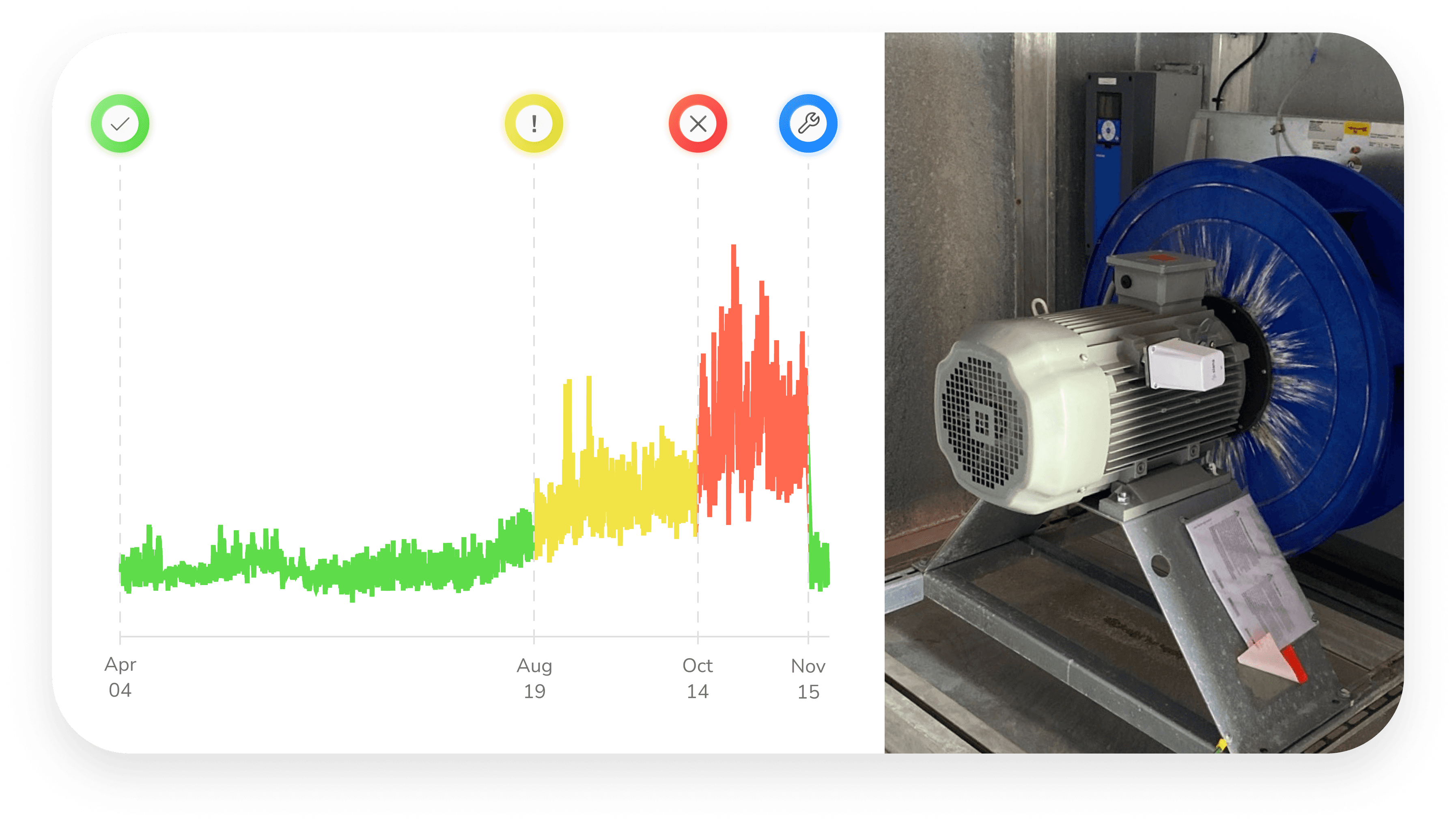

Failure Prediction

Autonomously detect failures in rotating equipment. Our fully automated training and diagnosis process provides reliable health analysis, showing when machines are running nominally, cautiously, or facing critical issues—so you can act with confidence.

Notifications

Stay informed with instant notifications for key events like failure predictions, training completions, and more. Delivered directly to your inbox or via SMS, with additional options coming soon—ensuring you never miss a critical update.

Works with Most Manufacturing Equipment

Seamlessly Integrated or Standalone - Your Choice

Whether you’re looking for a complete solution or want to enhance your existing setup, Siana has you covered. Our API makes integration possible with your SCADA or CMMS systems, allowing you to fetch and use uptime and maintenance data effortlessly. Siana is also designed to work as a standalone application.

Get in touch with our friendly experts and get a sneak peek with a live demo. We’re here to help.