Usage-based Maintenance

More Uptime, Fewer Headaches

Switching to maintenance based on machine uptime ensures your equipment gets the care it needs—when it needs it. Avoid unnecessary repairs, prevent unexpected breakdowns, and keep operations running smoothly with strategies tailored to a machines’ actual use.

Save Time

Cut Costs

Boost Reliability

Getting Started Has Never Been Easier

Device

+

+

Smartphone

=

=

Uptime Tracking

With our technology, there’s no need for complex IT setups or endless configuration. All you need is our sensor device and a smartphone. Simply install the sensor, connect through the app, and start tracking machine operating hours and maintenance data instantly. It’s that simple.

Main Benefits

Increased Maintenance Accuracy

Uptime-based maintenance focuses on the actual usage of a machine rather than arbitrary time intervals. This ensures that maintenance tasks are performed only when necessary, reducing both over-maintenance and under-maintenance.

Higher Operation Efficiency

Machines are maintained in optimal working condition, leading to fewer breakdowns, higher productivity, and more consistent performance.

Data-Driven Decision Making

Uptime-based maintenance often requires and benefits from robust data collection and analysis, fostering a data-driven approach to asset management.

Take the First Steps Toward Usage-Based Maintenance

Get in touch with our friendly experts and get started with your free trial.

Experience Siana Usage

Experience

Siana Usage

Trusted by Top Global Manufacturers

Packed with Powerful Features

Timers

Create timers to schedule and track maintenance tasks like bearing replacements or gear lubrication based on actual machine uptime, ensuring precise and timely servicing.

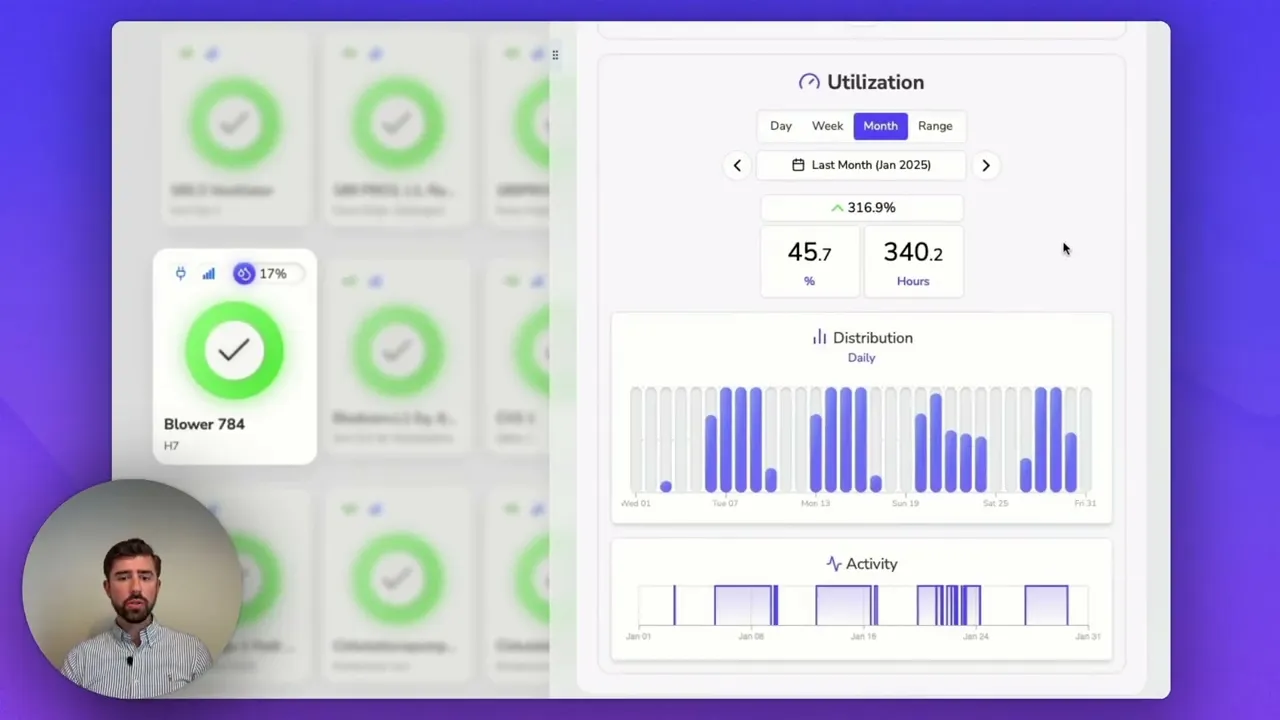

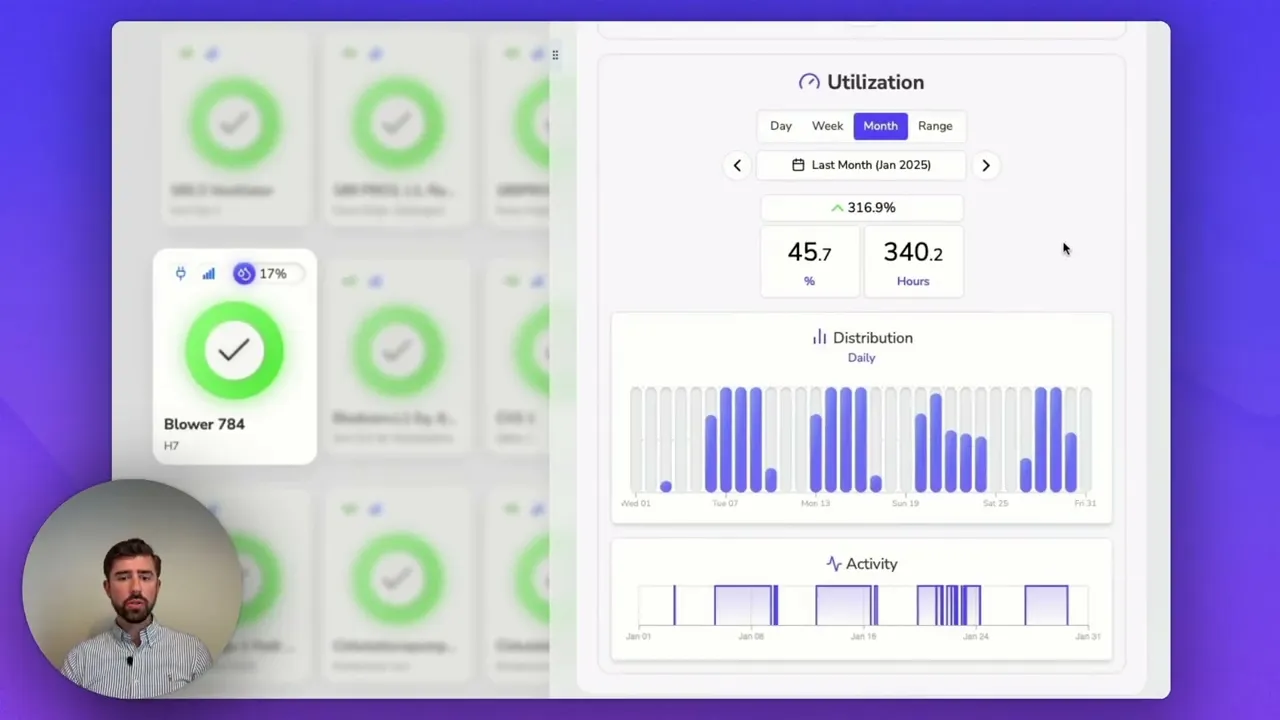

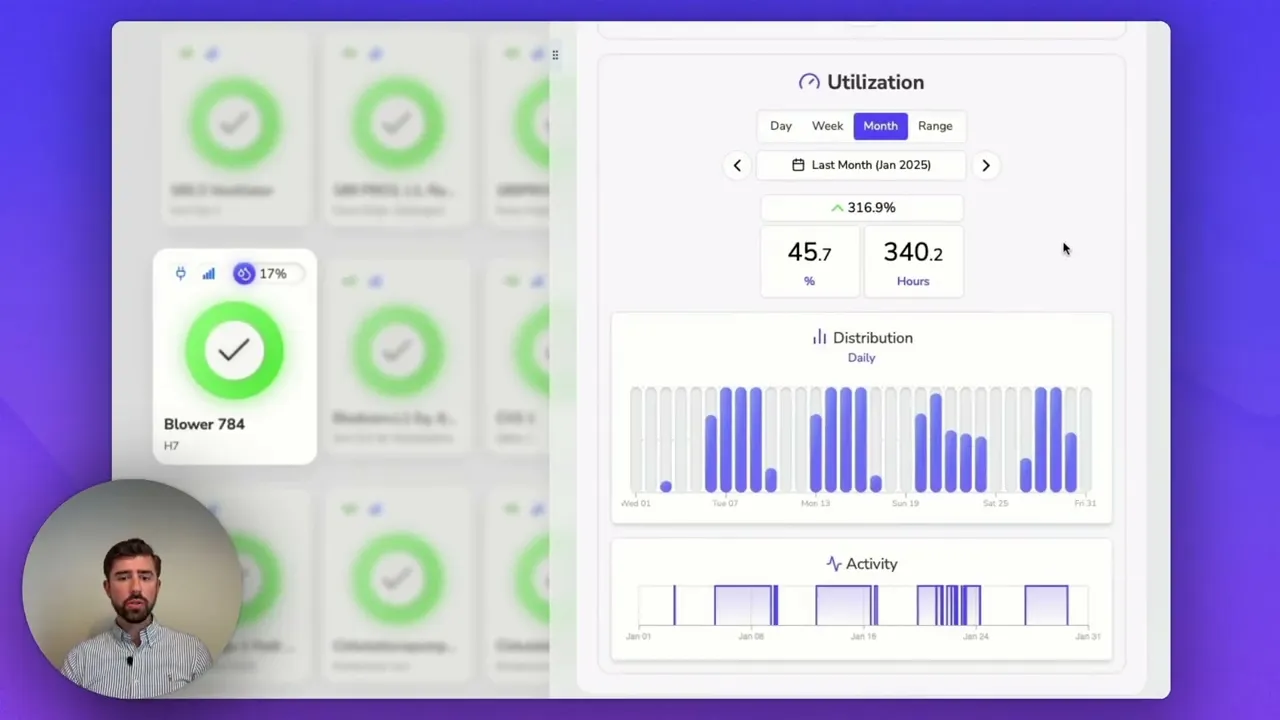

Utilization

Utilization provides a clear view of machine performance over hours, days, weeks, and months, helping you understand and optimize manufacturing efficiency.

2-minute Install

The installation process is quick and intuitive - set up the sensor and connect it to the cloud in just 2 minutes using our easy-to-follow app.

Works with Most Manufacturing Equipment

Electric motors

Pumps

Gear box

Compressors

Gearmotors

HVAC

Bearings

Electric motors

Pumps

Gear box

Compressors

Gearmotors

HVAC

Bearings

Seamlessly Integrated or Standalone - Your Choice

Whether you’re looking for a complete solution or want to enhance your existing setup, Siana has you covered. Our API makes integration possible with your SCADA or CMMS systems, allowing you to fetch and use uptime and maintenance data effortlessly. Siana is also designed to work as a standalone application.

Usage-based Maintenance

More Uptime, Fewer Headaches

Switching to maintenance based on machine uptime ensures your equipment gets the care it needs—when it needs it. Avoid unnecessary repairs, prevent unexpected breakdowns, and keep operations running smoothly with strategies tailored to a machines’ actual use.

Save Time

Cut Costs

Boost Reliability

Getting Started Has Never Been Easier

Device

+

Smartphone

=

Uptime Tracking

With our technology, there’s no need for complex IT setups or endless configuration. All you need is our sensor device and a smartphone. Simply install the sensor, connect through the app, and start tracking machine operating hours and maintenance data instantly. It’s that simple.

Main Benefits

Increased Maintenance Accuracy

Uptime-based maintenance focuses on the actual usage of a machine rather than arbitrary time intervals. This ensures that maintenance tasks are performed only when necessary, reducing both over-maintenance and under-maintenance.

Higher Operation Efficiency

Machines are maintained in optimal working condition, leading to fewer breakdowns, higher productivity, and more consistent performance.

Data-Driven Decision Making

Uptime-based maintenance often requires and benefits from robust data collection and analysis, fostering a data-driven approach to asset management.

Take the First Steps Toward Usage-Based Maintenance

Get in touch with our friendly experts and get started with your free trial.

Experience Siana Usage

Trusted by Top Global Manufacturers

Packed with Powerful Features

Timers

Create timers to schedule and track maintenance tasks like bearing replacements or gear lubrication based on actual machine uptime, ensuring precise and timely servicing.

Utilization

Utilization provides a clear view of machine performance over hours, days, weeks, and months, helping you understand and optimize manufacturing efficiency.

2-minute Install

The installation process is quick and intuitive - set up the sensor and connect it to the cloud in just 2 minutes using our easy-to-follow app.

Works with Most Manufacturing Equipment

Electric motors

Pumps

Gear box

Compressors

Gearmotors

HVAC

Bearings

Seamlessly Integrated or Standalone - Your Choice

Whether you’re looking for a complete solution or want to enhance your existing setup, Siana has you covered. Our API makes integration possible with your SCADA or CMMS systems, allowing you to fetch and use uptime and maintenance data effortlessly. Siana is also designed to work as a standalone application.

© Siana ApS 2025. All rights reserved.