Data-Driven Maintenance

An Overview

Siana combines advanced sensors, AI, and intuitive interfaces into a powerful software suite. It monitors machinery health, predicts maintenance, and optimizes operations to revolutionize manufacturing.

Technology

Our technology is designed to be user-friendly and seamlessly integrated into your maintenance processes. With our app and Siana Device, you can quickly start monitoring essential equipment and access machine health insights on our platform.

The Platform

Brief Overview

& Deep Insights

The Siana Platform provides clear machine health summaries with intuitive visuals and alerts, enabling quick assessments and proactive maintenance to prevent breakdowns.

Siana can also be seamlessly integrated into other systems.

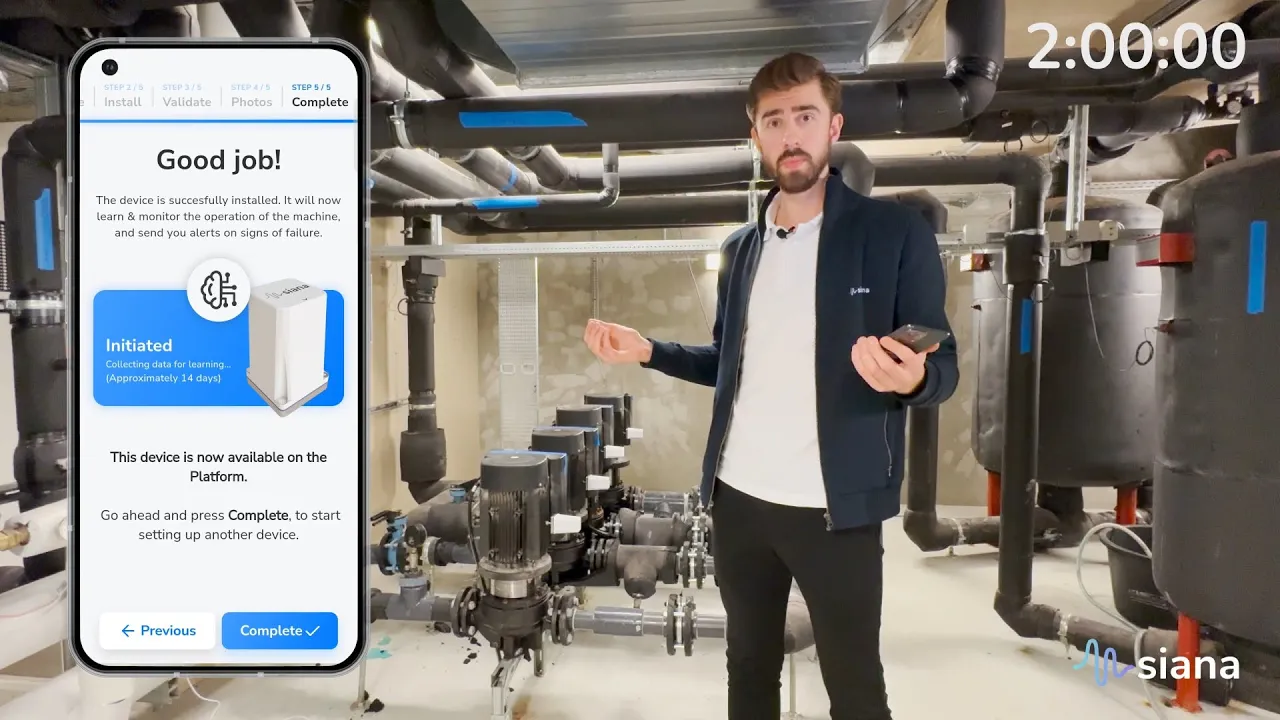

The App

Getting Started

is a Breeze

The Siana App simplifies device setup with a step-by-step interface and NFC connectivity. It ensures seamless installation, verifies functionality, and empowers you to maximize Siana’s predictive maintenance features.

The Device

Seems Simple, but Highly Advanced

The Siana Device gathers vibration and temperature data from machines, sending it via the nearest cell tower. Built with high-quality components and an IP69K rating, it’s durable, wireless, battery-powered, and designed for easy installation and reliable performance.

Data is send directly via the nearest mobile cell tower

No gateways or routers needed

No access to your local IT network needed

Can be powered by battery, or by fixed power supply

Getting Started

It all starts with the Siana Device. The setup process bears resemblance to that of well designed and high-end smart speakers and other smart home products. From blacksmiths, to electricians, everyone can setup the sensor and get started right away. It is done in 3 easy steps.

Connect

Install

Validate

Feature Plans

Whether you need powerful uptime tracking with our Usage plan or cutting-edge AI-driven predictive maintenance with Health, we’ve got you covered. Scale your maintenance strategy with the tools that fit your operations best.

Usage

Perform Usage-based Maintenance on your equipment with Machine Uptime Tracking

Includes

Machine Uptime Tracking

Accurate tracking using continuous vibration measurements

Timers & Stopwatches

Usage-based intervals for service, performance, etc.

Utilization

Uptime overview to reveal performance patterns and boost efficiency.

Machine Service Log

Store machine activities, photos and comments.

Notifications

Get notifications on important events, like service timers.

No Additional Fees

Everything needed to take full advantage of this plan is included from day one. This includes sensor, cloud software and more.

Health

Predict upcoming failures & plan preventive measures on machines, using AI-based Predictive Maintenance

Includes

Everything Included from

Usage

Machine Service Log

Timers & Stopwatches

Utilization

And more...

Health Analysis

Real-time estimate of machine health & upcoming failure predictions based on machine learning (AI).

Dynamic Listening

The sensor will intelligently only take measurements whenever the monitored machine is running.

Nerd Mode

Various analysis tools for diving deep into the data behind the health analysis, for further diagnostics.

Failure Alerts

Get Email and SMS notifications of upcoming machine failures well in advance.

No Additional Fees

Everything needed to take full advantage of this plan is included from day one. This includes sensor, cloud software and more.

Henrik Jacobsen

TPM Planner

Get in touch with our friendly experts and get a sneak peek with a live demo. We’re here to help.